Behind the Scenes of the Paper Making Process

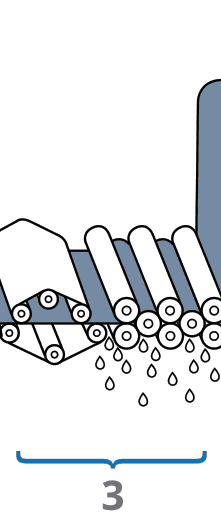

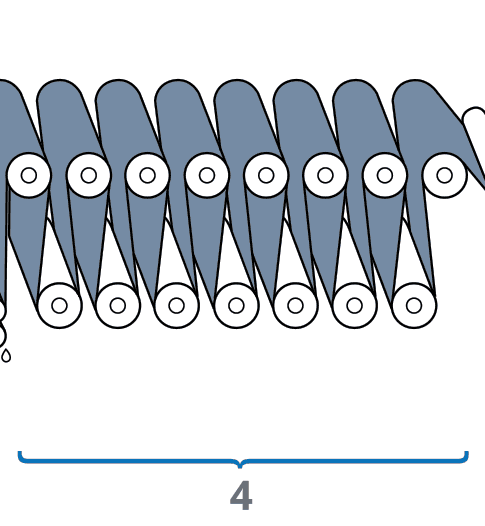

Thousands of years ago, people learned they could combine fibre and water into a slurry to create paper. While the basic concept has remained the same throughout the ages, today we do it on a much larger scale and at a much more advanced level of technology.

TURNING PULP INTO PAPER

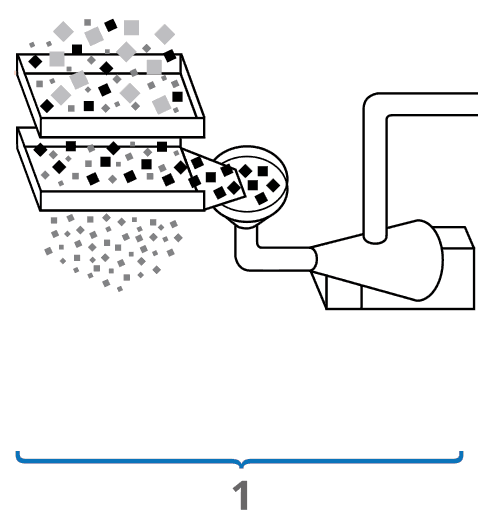

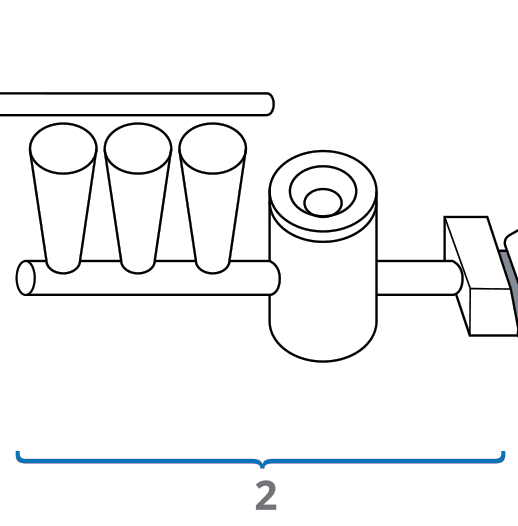

Making paper entails mixing different pulp grades to produce product with specific end-use characteristics. We blend varying combinations of mechanical and kraft pulps along with fillers and pigments to make our papers.

Mechanical pulp is used to produce our lightweight newsprint and directory products, while kraft pulp is used in limited amounts to add strength to our specialty papers. For brighter, whiter paper, we use higher brightness bleached pulp, using an elemental chlorine-free process.

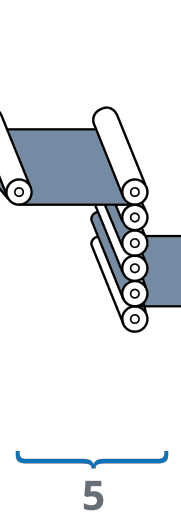

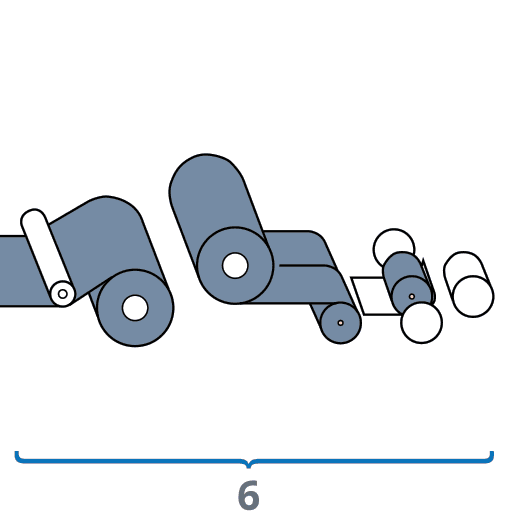

THE PAPER MAKING PROCESS

LOGISTIC SOLUTIONS

With our distinct approach to operational excellence, we provide superior, cost-effective products to domestic and international customers. A dedicated team utilizes a full range of logistics solutions, transportation modes, warehousing facilities and management data tools to deliver products to a wide range of Catalyst customers in a professional and efficient manner.

LEARN MORE