A STRONG COMMITMENT TO HEALTH AND SAFETY

At Paper Excellence, safety is our prime focus through the entire organization from our tree nursery to our manufacturing locations to our distribution center. We believe in helping protect our employees and contractors by providing safe working environments that meet all regulatory requirements.

Safety is of vital importance as it sets the tone for the manner in which we make our products and strive to improve our entire organization. Our safety management systems have adopted best in class approaches to measure our short and long-term performance and drive continuous improvement along the forest products value chain.

OUR SAFETY PHILOSOPHY

All of our facilities have site specific safety policies that help define their safety programs. In general, our overarching safety philosophy is:

OUR SAFETY APPROACH

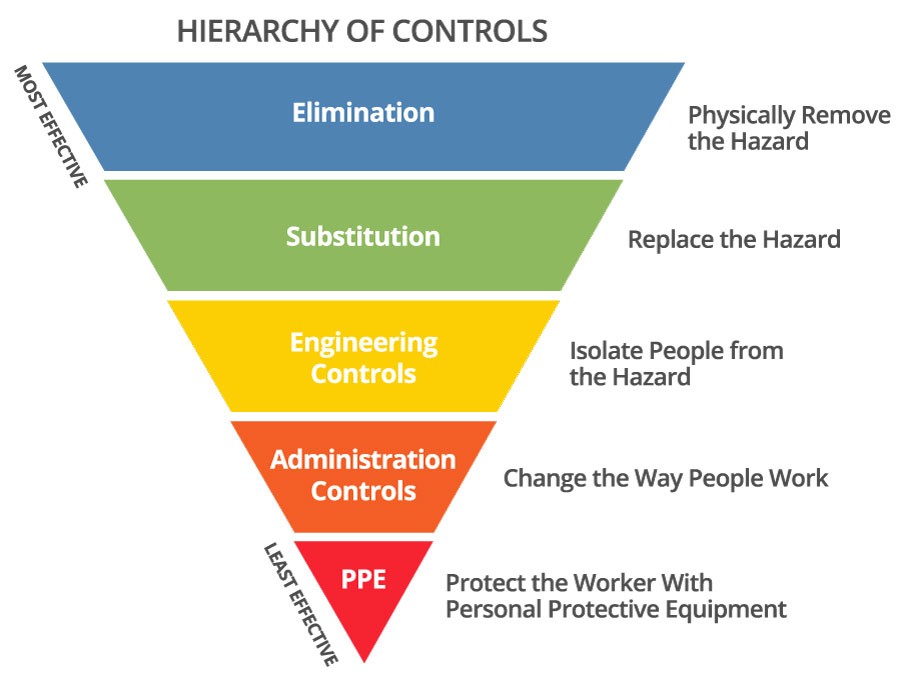

Our safety approach is founded on the internationally accepted hierarchy of controls which emphasizes elimination of risks instead of controls or protective equipment. At Paper Excellence, we first seek to remove or replace hazards with lesser ones, before adopting approaches to isolate employees from risk. Our final and least preferred methodology involves either modifying how employees work around equipment or fitting them with personal protective equipment to reduce significance of injuries. This hierarchy is embraced by leading organizations as the right way to achieve world leading safety performance.

OUR SAFETY MANAGEMENT SYSTEMS

Each of our facilities has a safety management system that is the heart of their safety program and our systems drive us toward continual improvement in all facets of safety. The eight key components of our program are reflected in the diagram.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

MANAGEMENT LEADERSHIP AND COMMITMENT

Our management leadership and commitment reflects our safety policies and the unwavering commitment from our company and mill leaders to pursue best in class safety performance. And the belief that all injuries are preventable.

SAFE WORK PROCEDURES AND WRITTEN INSTRUCTIONS

Our safe work procedures and written instructions guide our employees on how to operate our equipment.

TRAINING AND INSTRUCTION OF WORKERS

Our training and instruction of workers is key to providing our people with the tools and knowledge to safely oversee our facilities and their processes.

HAZARD IDENTIFICATION AND CONTROL

Our hazard identification and control procedures are critical to proactively identifying dangers within our facilities and building out solutions to those challenges before operations are started.

INSPECTIONS OF OUR WORKPLACES

Inspections of our workplaces play a key role in ensuring that we constantly monitor the safety conditions for our workers and involve and empower them to undertake these audits creating better knowledge and ownership of safety.

INVESTIGATION OF INCIDENTS

Unfortunately, investigation of accidents and near misses is an important tool in understanding root causes of events as an approach to developing and implementing solutions to prevent recurrence.

PROGRAM ADMINISTRATION

Our program administration captures our safety performance data and tracks issues relating to incidents, corrective actions and investigations. It also sets annual priorities and goals for each mill to maximize its safety performance.

JOINT HEALTH AND SAFETY COMMITTEES

Our joint health and safety committees are critical venues for the company and union leadership to jointly develop and deploy safety programs, discuss safety improvement opportunities, and to work to overcome complex problems – ensuring transparency in our safety programs and the protection of all workers.

110,000

In 2018, the company purchased over 110,000 pairs of gloves (of numerous varieties) to help protect employees hands.