The Science Behind Our Kraft Pulp Process

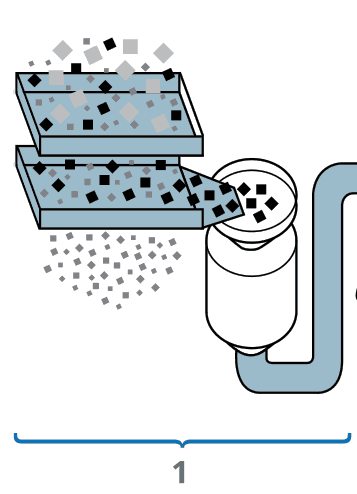

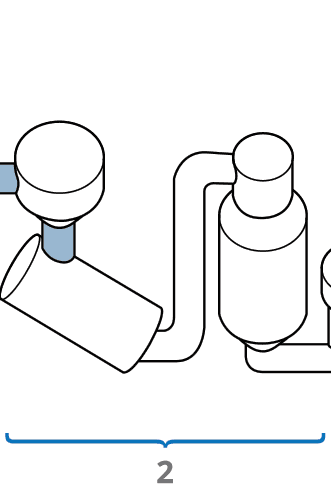

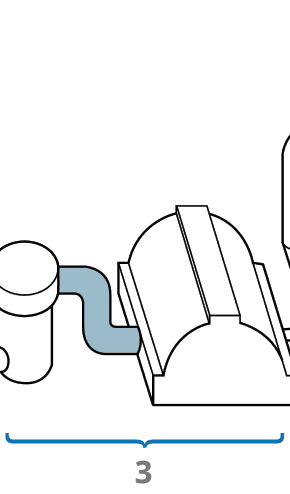

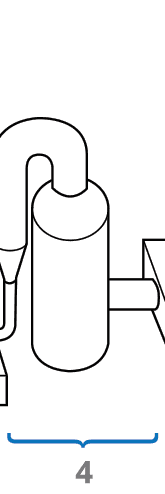

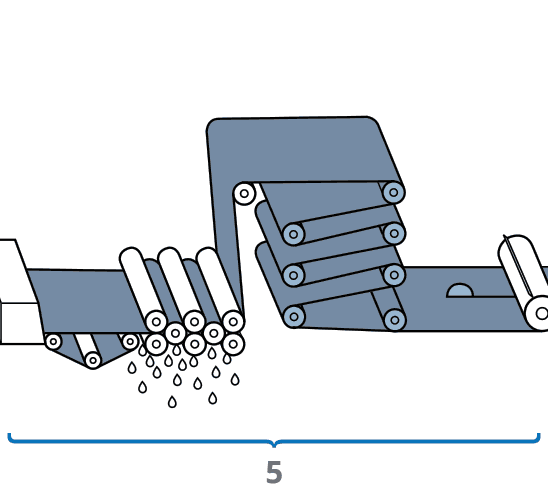

The essential elements for making kraft pulp are wood fibre, water, chemicals and heat. We make kraft pulp by mixing wood fibres with a solution of caustic soda and sodium sulphide, and cooking them inside a digester. This separates the fibres from the lignin, which is a natural glue-like substance that binds them together. Our production facilities are designed to recover and reuse much of the water, chemicals and steam used in the process.

THERMO-MECHANICAL PULP

Paper Excellence sells its kraft pulp externally to customers around the world. Some of Paper Excellence’s Canadian mills also produce a type of mechanical pulp, referred to as thermo-mechanical pulp or TMP, for use in making their own paper products (see How We Make Paper). Our Meadow Lake mill makes Bleached Chemi Thermal Mechanical Pulp (BCTMP) which is a hybrid of kraft and TMP.

ENVIRONMENTAL ASSURANCE

The fibre we use to make kraft pulp is mainly made up of leftovers from lumber mills. These wood chips and shavings were once considered waste and sent to landfills or burned. We match tree species and other pulp characteristics with customers’ end-use requirements, and control blending and bleaching to exacting specifications.

PUTTING SAWMILL LEFTOVERS TO USE

As with all products from our Canadian mills, our kraft pulp is made from responsibly sourced fibre and in facilities that have achieved sector-leading greenhouse gas reductions. We use a lower-impact elemental chlorine-free bleaching process. With our chain-of-custody systems using globally recognized standards, we can provide pulp and paper products that are certified as originating from sustainably managed forests for those customers wishing additional assurance.