CHAIN OF CUSTODY POLICY

Paper Excellence commits to its customers that it will provide products that conform to recognized environmental protection standards. This commitment starts with the procurement and subsequent use of wood fibre in the Company’s manufacturing process.

The Company relies on professional, independent third parties to verify that the wood fibre used within its products.

- Is not sourced from illegally harvested wood

- Is not harvested in violation of traditional and civil rights

- Is not harvested from forests where high conservation values are threatened by management activities

- Is not from plantations or lands being converted into plantations or non-forest use

- Is not from genetically modified trees

- Is not in violation of any International Labour Organization Core Conventions

OUR TEAMS OF PROCUREMENT MANAGEMENT PROFESSIONALS ENSURE THAT:

100% of our fibre comes from well managed, sustainable North American forests.

100% of our fibre is managed under our chain of custody programs. Our mills use globally recognized standards.

100% of our fibre supply is covered by our Due Diligence System allowing us to mitigate risk.

SUPPLY CHAIN TRANSPARENCY

The Company is a strong supporter of supply chain transparency through recognized, third party certification systems that are independently verified to ensure fibre meets important standards of conservation and sustainability.

Transparent and Responsible Supply Chain Practices

Transparency is a cornerstone of our fibre supply chain management. At Paper Excellence, supply chain transparency means providing clear information about where and how our wood fibre is sourced. Our forest management and fiber procurement is certified by international standards and audited by third parties. We believe this transparency is key to building trust with our customers, partners, and the communities we operate in.

The Company undertakes continual review and improvement of our chain of custody systems including our alignment and integration with our company wide environmental management system. The Company also commits to protect our workers with active occupational health and safety programs.

FIBRE FROM WASTE WOOD

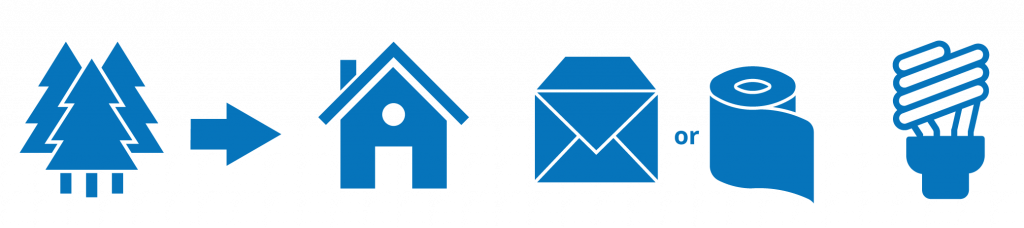

Over 60% of our raw fibre comes as sawmill waste wood chips. Saw logs are converted at sawmills into dimensional lumber for homes. The by-product or residual chips come to our facilities for our pulp and paper products while we use the log’s bark to generate green energy.